Why Additive Manufacturing Is More Than Just 3d Printing

Introduction to Additive Manufacturing

In the realm of modern manufacturing, additive manufacturing stands as a transformative force, yet it is often conflated with 3D printing. Additive manufacturing is a sophisticated process of creating objects by adding material layer by layer, offering more than just three-dimensional printing capabilities. It encompasses a range of technologies that are revolutionizing industries from aerospace to healthcare. The central theme is the remarkable potential to design and produce complex structures with unmatched precision and customization. Understanding why additive manufacturing is more than merely 3D printing opens up a world of innovation and efficiency in production.

Advertisement

The Evolution Beyond 3D Printing

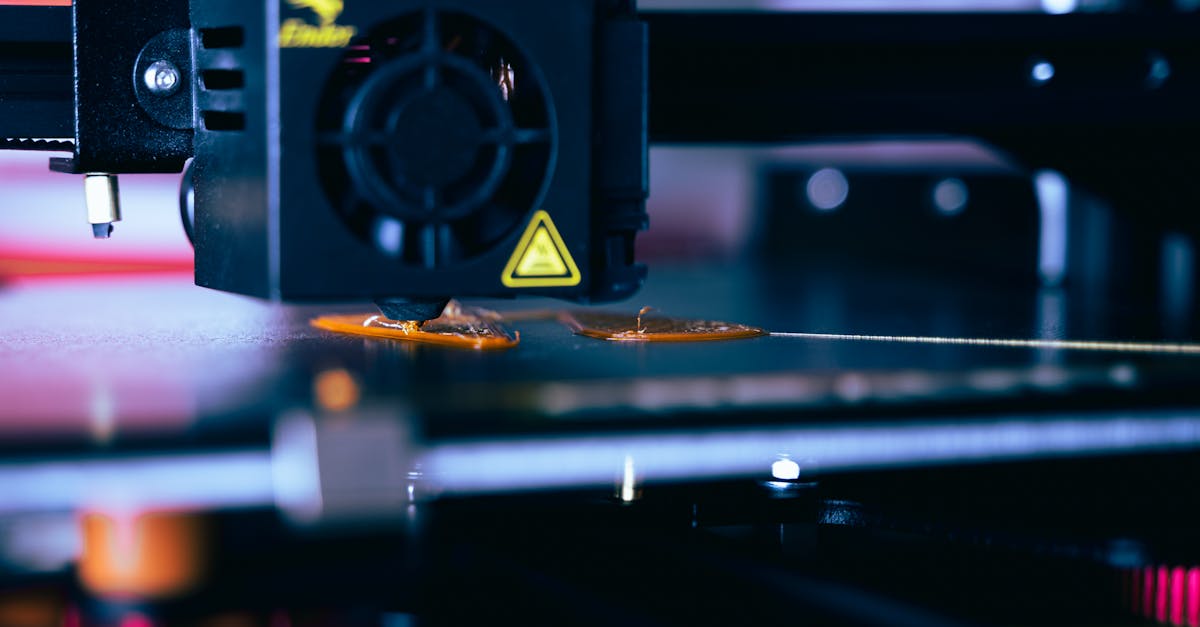

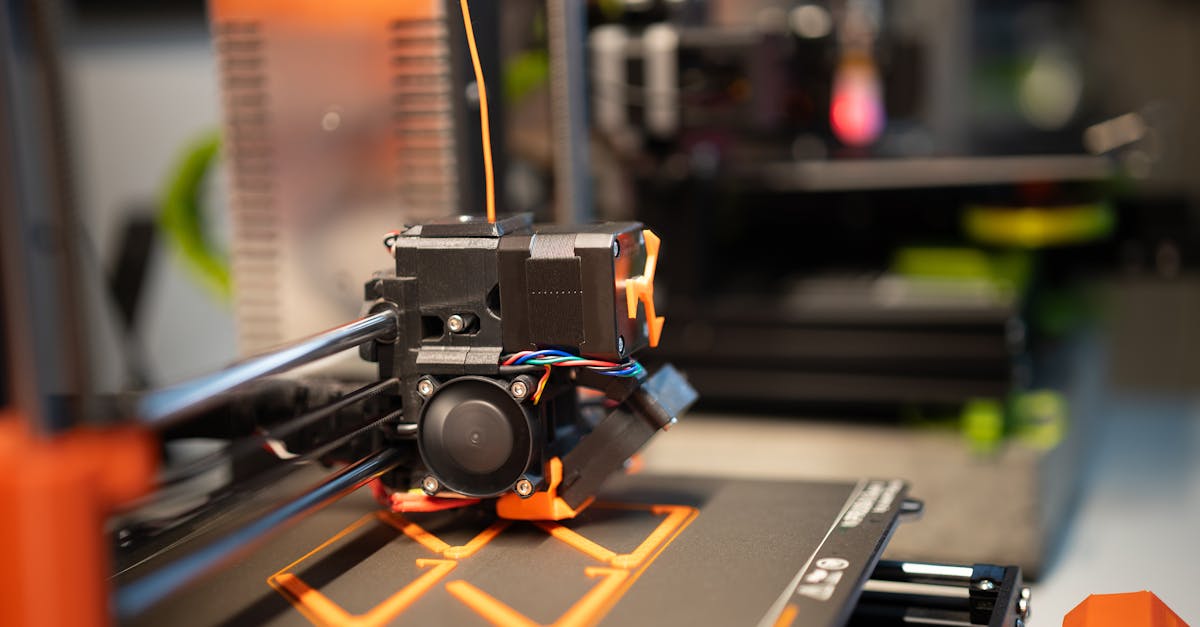

3D printing initially emerged as a prototyping tool in the 1980s, capturing imaginations with its ability to quickly produce physical models. However, additive manufacturing has since evolved into a comprehensive approach, incorporating a variety of techniques such as selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA). Each method brings unique strengths, allowing manufacturers to select the best approach based on materials, complexity, and end-use applications. Unlike traditional methods which subtract material, additive manufacturing reshapes how we think about sustainability and material efficiency.

Advertisement

Unrivaled Design Freedom

One of the greatest benefits of additive manufacturing is the unparalleled design freedom it provides. Traditional manufacturing often places limits on complexity due to tool-path restrictions, but additive techniques allow designers to create intricate geometries that were once considered impossible. This freedom inspires innovation, from lightweight yet sturdy lattices in aerospace to patient-specific implants in medicine. By unlocking new design possibilities, additive manufacturing fuels creativity, enabling engineers and designers to push boundaries and redefine capabilities in their respective fields.

Advertisement

Materials Matter More Than Ever

While 3D printing was initially associated with plastics, additive manufacturing has expanded to utilize diverse materials, including metals, ceramics, and even biologics. Each material offers distinct properties, from high-strength alloys for aerospace components to biocompatible materials used in medical implants. This diversity broadens the application scope across industries, allowing for customized solutions that meet specific functional requirements. The ability to work with various materials enhances the relevance and adaptability of additive manufacturing in solving real-world challenges.

Advertisement

Efficiency and Sustainability

The precision layer-by-layer approach of additive manufacturing means it inherently produces less waste compared to subtractive manufacturing processes. By precisely using minimal material, companies can dramatically reduce production costs and environmental impact. Additionally, the decentralized nature of additive manufacturing allows for localized production, eliminating the need for long supply chains and reducing carbon footprints. These aspects align additive manufacturing with contemporary goals of sustainability and cost-efficiency, offering businesses a competitive advantage in a resource-conscious world.

Advertisement

Prototyping and Beyond

While additive manufacturing is synonymous with rapid prototyping, its scope extends far beyond. It has empowered industries to undertake small batch productions, custom tooling, and even end-use part manufacturing. The agile nature of additive techniques means they can quickly adapt to produce different designs without the need for exhaustive retooling or setup. This flexibility translates into real competitive advantages, enabling companies to respond swiftly to market demands or product iterations. The ability to seamlessly transition from prototype to full-scale manufacturing sets additive production apart.

Advertisement

Industry Impact and Innovation

Industries from aviation to healthcare witness substantial benefits and innovations powered by additive manufacturing. In aerospace, manufacturers produce lightweight components that significantly improve fuel efficiency. Automotive companies leverage it for prototyping and custom tooling, reducing lead times. Healthcare has seen rapid advancement in patient-specific prosthetics and implantable devices, enhancing patient outcomes and personalization. Across industries, additive manufacturing has introduced novel approaches to age-old problems, accelerating progress and redefining industry standards.

Advertisement

Challenges and Opportunities

Despite its promising potential, additive manufacturing faces certain challenges. Material performance consistency, high initial capital investment, and the need for skilled workers are some areas requiring attention. Nonetheless, these challenges present opportunities for innovation and growth, especially with ongoing advancements in materials science and automation. As more sectors harness its possibilities, overcoming these hurdles could place additive manufacturing as a cornerstone in future production landscapes, paving the way for smarter manufacturing solutions.

Advertisement

The Road Ahead

The future of additive manufacturing holds exciting prospects as technology continues to advance. Continual improvements in speed, precision, and material capabilities promise to further expand its applications. The convergence with new technologies, such as artificial intelligence and IoT, opens possibilities for smarter, more integrated manufacturing solutions. Educational initiatives and industry collaborations pave the way for expanded expertise and skillsets, ensuring the workforce is well-equipped to harness the full potential of additive methodologies.

Advertisement

Conclusion and Continued Evolution

Additive manufacturing is evolving beyond its 3D printing origins, encompassing a breadth of technologies reshaping how products are designed, produced, and applied. Its capacity to innovate, foster sustainability, and offer unparalleled customization positions it as a revolutionary force in modern manufacturing. By transcending the restrictions of traditional methods, additive manufacturing continues to uplift industries, ensuring they remain dynamic, responsive, and capable of addressing future challenges. As we explore this promising landscape, it is evident that additive manufacturing is more than a technological leap—it is the future of production.

Advertisement