Smart Factories and Industry 4.0 Revolutionizing Production

Introduction

The onset of the Fourth Industrial Revolution, often termed Industry 4.0, is reshaping manufacturing and production as we know it. At the center of this revolution are smart factories—advanced production systems that leverage cutting-edge technology. But what exactly are smart factories, and how do they integrate digital innovations into traditional manufacturing? As we dive into the world of Industry 4.0, it becomes evident that connectivity reigns supreme, linking machinery, data, and humans in unprecedented ways. With automation, artificial intelligence, and the Internet of Things (IoT) playing pivotal roles, the landscape of production is evolving rapidly. This article delves into the transformative power of smart factories and their impact on modern industry.

Advertisement

The Essence of Smart Factories

Smart factories represent a new paradigm in manufacturing, characterized by digital processes interwoven with automation and real-time data analytics. Unlike traditional factories, these advanced facilities harness interconnected systems that communicate seamlessly. Sensors embedded in machinery collect valuable data, providing insights into operations and informing decision-making processes. Artificial intelligence and advanced computing play key roles, optimizing production by predicting maintenance needs and adjusting workflows. This synergy of technology improves efficiency, reduces downtime, and enhances quality control, marking a stark progression from earlier industrial models.

Advertisement

Core Technologies Driving Innovation

Several core technologies underpin the operations of smart factories. The Internet of Things (IoT) forms the backbone, linking machinery and equipment through the internet for constant communication. Advanced robotics introduces precision and consistency, with robots taking on tasks that demand exacting standards. Big data analytics processes vast amounts of data, providing comprehensive insights that enhance productivity and decision-making. Meanwhile, cloud computing offers vast storage and processing capabilities, enabling remote monitoring and control of operations. Together, these technologies build an agile and responsive production environment.

Advertisement

Efficiency and Productivity Gains

Smart factories promise significant efficiency gains by reducing wastage and optimizing resource use. Traditional manufacturing frequently encounters bottlenecks due to unforeseen equipment failures. In contrast, predictive maintenance systems within smart factories preemptively address potential problems. Real-time data analytics ensures smoother workflows and streamlines production schedules, minimizing downtime. Enhanced communication between integrated systems results in faster reaction times and improved adaptability to changing market dynamics. Consequently, these advancements contribute to significant productivity enhancements and cost savings.

Advertisement

Impact on the Workforce

While smart factories automate many tasks, they also usher in opportunities for workers to focus on more strategic roles. The shift from manual operation to oversight and programming demands new skillsets, fostering opportunities in technology management and data analysis. Industry 4.0 calls for a workforce that is adaptable and proficient in technical disciplines, prompting educational institutions to realign curricula. However, this shift has also raised concerns about job displacement and the widening skills gap, spurring initiatives to retrain and upskill existing workers to thrive in this evolving landscape.

Advertisement

Sustainability and Environmental Benefits

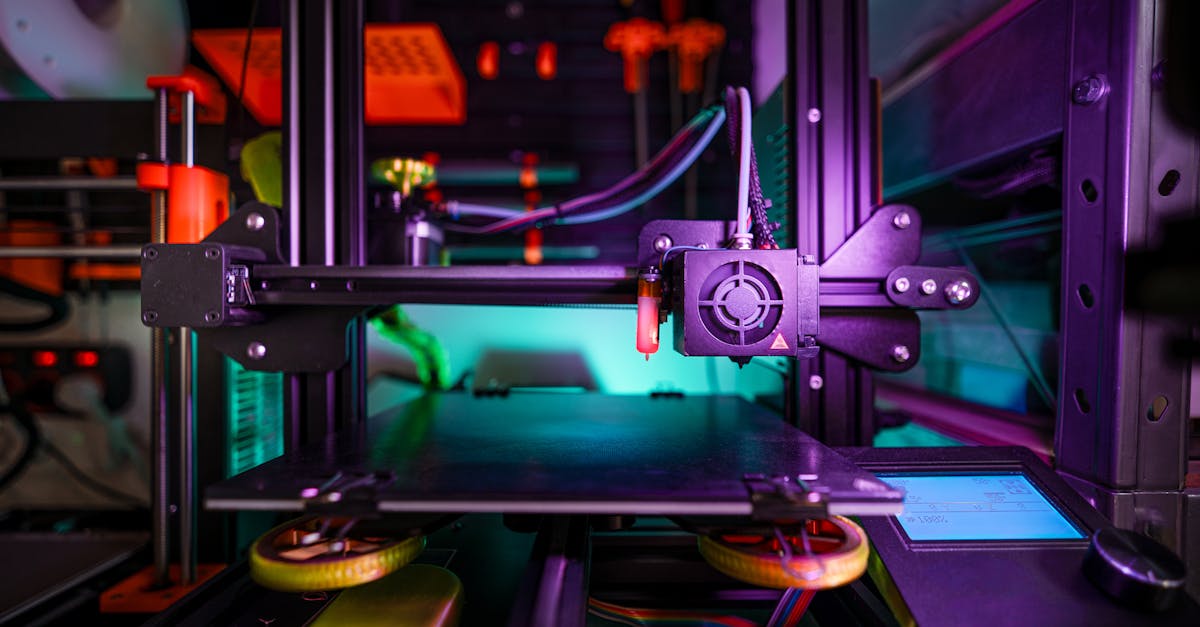

The integration of smart technology in factories also brings notable environmental benefits. Advanced monitoring systems optimize energy consumption, reducing the carbon footprint of production activities. Efficient resource management minimizes waste generation, promoting sustainability in manufacturing processes. Innovations such as 3D printing reduce material usage, while closed-loop systems recycle and reuse resources, further enhancing environmental stewardship. Smart factories exemplify how technology can be harnessed to create eco-friendly and sustainable production systems, addressing the growing global emphasis on environmental conservation.

Advertisement

Challenges and Barriers to Adoption

Despite the promising prospects of smart factories, their adoption faces several challenges. High initial investment costs act as barriers, particularly for small and medium-sized enterprises (SMEs). Additionally, integrating advanced digital systems into legacy infrastructure requires careful planning and execution. There's also an inherent risk of data breaches and cybersecurity threats due to increased connectivity. Businesses must navigate these challenges by fostering innovation, investing in robust cybersecurity measures, and developing scalable solutions. Collaboration between industry stakeholders and technology providers is key to overcoming these barriers.

Advertisement

Global Implications of Industry 4 0

The global implications of smart factories and Industry 4.0 are profound, influencing economies and cultures across the world. Countries with advanced infrastructure stand to benefit significantly, with enhanced competitiveness in international markets. Conversely, regions lagging in technology may experience widening economic disparities. Furthermore, international trade dynamics may shift due to changes in production capacities. Collaborative efforts for knowledge exchange, standardization, and cross-border innovation thus become crucial. As nations navigate this industrial evolution, the role of policy-makers in supporting fair and sustainable development is paramount.

Advertisement

Future Trends and Innovations

As technology continues to evolve, the future of smart factories appears promising, with emerging trends set to redefine them further. Quantum computing may offer new possibilities in data analysis, substantially increasing processing capabilities. The expansion of 5G networks promises faster and more reliable connectivity, enhancing communication between devices and systems. Augmented reality and digital twins could revolutionize product design and maintenance by providing immersive and interactive experiences. These innovations will likely drive the next generation of smart factories, pushing the boundaries of what is possible in industry.

Advertisement

Conclusion

In conclusion, smart factories and the Industry 4.0 revolution are dramatically reshaping the landscape of production. By leveraging technological advances in connectivity, data analytics, and automation, these modern marvels of industry enhance efficiency, productivity, and sustainability. However, the journey to fully realizing the potential of Industry 4.0 requires overcoming significant challenges, including investment barriers and workforce adaptation. As society continues to embrace these innovations, the smart factory model symbolizes the future of manufacturing—one that is efficient, sustainable, and technologically advanced. Embracing collaborative efforts between industries and governments will ensure a balanced and equitable transition into this new era.

Advertisement